Foshan, China, 1st Apr 2024 – Quartz slabs have become a popular choice for countertops, flooring, and other surfaces in homes and commercial spaces. These durable and stunning slabs are made through a meticulous manufacturing process that involves various steps. In this article, we will explore the process of manufacturing quartz slabs in detail.

What is Quartz?

Before diving into the manufacturing process, let’s first understand what quartz is. Quartz is a mineral composed of silicon and oxygen atoms in a continuous framework of SiO4 silicon–oxygen tetrahedra. It is one of the most abundant minerals in the Earth’s crust and has a wide range of industrial applications due to its hardness and durability.

Mining and Selecting Raw Materials

The manufacturing process of quartz slabs starts with the mining of quartz crystals. These crystals are found in quartz mines and are extracted using heavy machinery. Once the quartz crystals are mined, they are carefully selected based on their quality and purity.

Crushing and Grinding

After the raw quartz crystals have been selected, they are crushed and ground into fine particles. This process helps to break down the quartz crystals into smaller sizes, making them easier to work with in the subsequent manufacturing steps.

Mixing and Adding Resins

The crushed quartz particles are then mixed with resins and other additives to create a paste-like mixture. The resins help to bind the quartz particles together and provide the slabs with additional strength and durability. Various pigments can also be added to the mixture to achieve different colors and patterns.

Molding and Pressing

Once the quartz mixture is ready, it is poured into molds and pressed using specialized machinery. The molds are designed to give the quartz slabs their desired thickness and dimensions. The pressing process helps to compact the quartz particles and remove any air bubbles, ensuring a smooth and uniform surface.

Curing and Heating

After molding and pressing, the quartz slabs are placed in ovens for curing and heating. This process helps to harden the resins and bind the quartz particles together permanently. The slabs are heated at high temperatures for a specific period to achieve the desired strength and durability.

Polishing and Finishing

Once the quartz slabs have been cured and hardened, they undergo a polishing and finishing process. Specialized machines are used to grind and polish the surface of the slabs, giving them a smooth and glossy finish. Various finishes, such as matte or glossy, can be achieved based on the customer’s preferences.

Quality Control and Inspection

Before the quartz slabs are ready for market distribution, they undergo rigorous quality control and inspection processes. Each slab is carefully examined for any defects or imperfections, ensuring only high-quality products are delivered to customers. Any flawed slabs are discarded, and only the best ones make it to the market.

Packaging and Distribution

Once the quality control process is complete, the quartz slabs are packaged and prepared for distribution. The slabs are carefully wrapped and protected to prevent any damage during transportation. They are then shipped to retailers, distributors, and customers around the world.

In conclusion, the manufacturing process of quartz slabs is a complex and intricate process that involves various steps, from mining and selecting raw materials to polishing and finishing. By understanding the manufacturing process, consumers can appreciate the craftsmanship and effort that go into creating these stunning and durable quartz slabs.

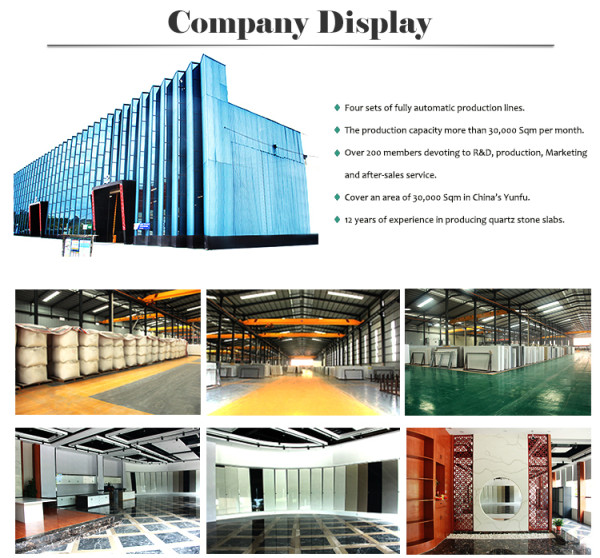

Bestone was founded in 2007. We founders came together with a shared dream: Build a life with the best stone. Our passion, expertise, and determination laid the foundation for Bestone, a leading manufacturer and exporter of artificial quartz stone slabs in China. Our stone products have been exported to 109 countries.

We provides Complete Stone Solution for Global Customers with all kinds of Natural & Artificial Stone – Marble, Granite, Onxy, Quartz Stone, Solid Surface, Artificial Marble, Sintered Stone as well as Stone Mosaic. With the ability of Designing, Plotting & Fabricating, Bestone is able to provide project services for Hotel, Condo, Apartment, Villa, Commercial & Domestic Home Projects.

In conclusion, when it comes to selecting the best quality silica-free quartz stone countertops for your home, Bestone is the supplier you can trust. With a commitment to excellence, unparalleled expertise, and a dedication to customer satisfaction, Bestone stands out as the top choice for premium countertops. Upgrade your space with the best of the best – choose Bestone Quality Silica Free Quartz Stone Countertops Supplier today.

Meta Description: Upgrade your home with premium quality silica-free quartz stone countertops from the leading supplier, Bestone. Transform your space today!

BESTONE HIGH TECH MATERIALS CO., LTD.

Whatsapp: +86 137 6331 1804

Website: https://www.bstquartz.com/

Mr. Tay Suen

TEL: +86 137 6331 1804

EMAIL: tay@bstquartz.com

Foshan, Guangdong, China

Media Contact

Organization: BESTONE HIGH TECH MATERIALS CO., LTD

Contact Person: Mr. Tay Suen

Website: https://www.bstquartz.com/

Email: info@bstquartz.com

Contact Number: +8613763311804

Address: Office: Rm. 1504-1505, Building 7, Tian’an Center No. 31, East Jihua Rd, Guicheng, Nanhai

Address 2: Guangdong,China

City: Foshan

Country: China

Release Id: 01042410805

The post Quartz Slabs Manufacturing Process Everything You Need to Know appeared first on King NewsWire. It is provided by a third-party content provider. King Newswire makes no warranties or representations in connection with it.

Disclaimer: The views, suggestions, and opinions expressed here are the sole responsibility of the experts. No journalist was involved in the writing and production of this article.